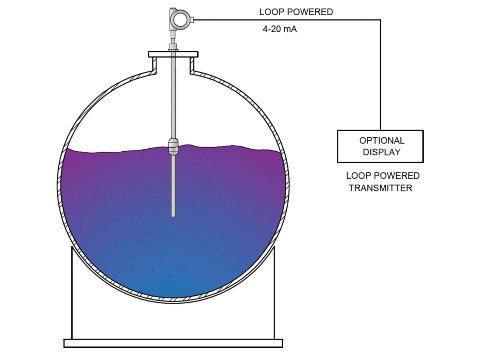

LTM Magnetostrictive level transmitters offer accurate, safe and reliable continuous level indication and control in hazardous and non-hazardous applications. The LTM is a loop-powered 24VDC liquid-level transmitter available as a direct insertion transmitter or as an external mounted transmitter onto a Magnetic Level Indicator for non-invasive level control. The LTM’s design is customized to meet the process condition and communication protocol requirements and can be configured for liquid level or interface applications.

Overview

The LTM Magnetostrictive level transmitter operation is based on the principle of Magnetostrictive technology. The sensor consists of an alloy wire called the wave guide housed inside the stainless-steel tube, creating the probe assembly. The electronics generate a current pulse which travels down the length of the wave guide. When the pulse interfaces with the floats magnetic field, a torsional force is produced, sending a return back to the electronics. A timing circuit measures the time-of-flight and the distance to the float (level) is precisely determined and presented as a 4/20mA output signal.

LTM Magnetostrictive level sensors are commonly used in storage tanks, fuel depots, wet scrubbers and chemical injections tanks for their highly accurate measurement. Due to their design, these sensors are unaffected by changes in electrical characteristics, heavy vapors, emulsion layers, condensation or foam – conditions that challenge other level technologies.

Direction Insertion LTM transmitters, referred to as standalone (S) units, are available in two models – LTM-250S and LTM-350S. Both feature explosion-proof, dual compartment enclosures with integral displays and are CSA-US approved for Class 1 Div.1 Explosion Proof area installations.

LTM liquid level sensors offer the latest and most advanced software features on the market, including HART and FOUNDATION Fieldbus (LTM-350). The “plug-and-play” electronics allow easy upgrades from HART to Fieldbus without replacing the sensor probe. Optional remote mounted electronics up to 25’ are available for easy access or high temperature applications.

For ordering information, refer to ordering information below. Not sure what model is right for your application, fill out the data application PDF.

Direct Insertion Magnetostrictive Transmitter

Features

- Simple mounting and installation

- Direct insertion for a wide variety of tanks and applications

- High resolution 4/20mA output

- On board diagnostics for troubleshooting

- Threaded or flange connections

- Measurement of total or interface level

- HART or FOUNDATION Fieldbus (LTM-350S)

- Stainless Steel enclosures & dual float configuration available

Industries

- Marine

- Chemical

- Oil and Gas

- Petrochemical

- Power Generation

- Water and wastewater

- Mining and minerals

Applications

- Interface measurement

- Position Sensing

- Valve Positioning

- Inventory Control

- Corrosive Process

- Batching Process

- Underground Tanks

- Primary Level/Interface

- Process Temperature and Level

Specifications

Electrical

Supply Voltage: 13 to 36 VDC

Analog Output:(1) 4/20mA primary level

Output: Primary level, (1) 4/20mA optional digital outputs via HART for Temperature or interface detection

Operating Temperature: Electronics) -58 to 185 F (-50C to 85C)

Performance

Repeatability: .005% of full scale or .010 in., whichever is greaterl

Non-Linearity: .01% of full scale or .030 in., whichever is greaterl

Sensor Accuracy: .01% of full scale or .030 in., whichever is greaterl

Resolution: .025% of full scalel

Dampening: 1 to 25 seconds (field adjustable via display)

Environmental

Housing: Explosion proof, dual compartment, 1/2in NPT, epoxy coated Aluminum, NEMA 4X, 7 (Stainless steel - Optional)

Approvals: CSA-USA Explosion Proof Class I, Div. I Groups B, C, D, E, F, G Class III, NEMA 4X, IP66

Transmitter Sensor Tube

Material: 316 Stainless Steel standard

Operating Temperature: -50 to 300 F (-50 to 150 C)

Max. Pressure: 2000 PSI @ 300 F

Range: 12 inches to 30 ft.