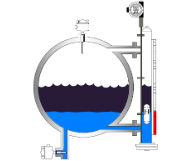

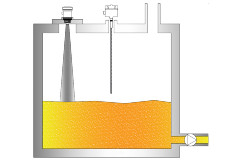

Oil Separator

Continuous level and interface measurement and point level detection in separators.

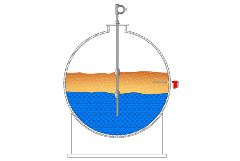

Interface

Point Level detection and continuous level measurement in interface applications.

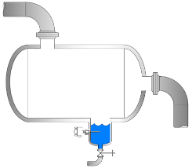

Condensate Pot

Point Level detection in condensate knockout pots.

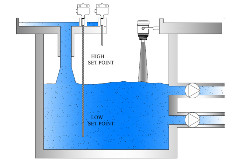

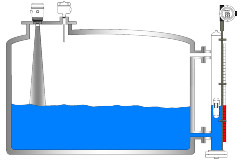

Wastewater Sump

Point level, dual point level detection and continuous level measurement in wastewater sump.

Crude Oil Storage

Continuous level measurement and point level detection for crude oil storage.

Liquid Storage Tank

Continuous measurement and point level detection in liquid material storage tanks.

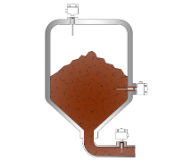

Powder & Bulk Solid Storage

Point Level detection in powder and dry bulk solid storage tank, hopper, bin or silo.

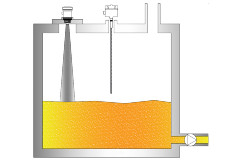

Hydraulic Reservoir

Continuous level measurement and point level detection in hydraulic oil reservoir.

Real World Examples

Examples of real world applications and the level measurement solutions Babbitt provided.