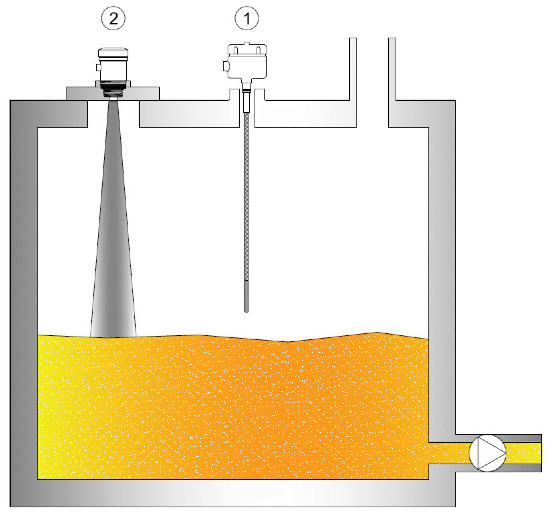

Point level detection and continuous level measurement in hydraulic oil reservoir

Application

Hydraulic fluid provides energy transmission through a system, enabling work and motion to be accomplished. Overtime, hydraulic fluid is slowly lost due to heat, lubrication or leakage inside equipment. Maintaining adequate level within the hydraulic reservoir tank is vital to the proper operation of power equipment.

Point Level Switches provide simple, reliable high or low level alarm indication. These units can be utilized as either a primary or secondary instrumentation to provide redundancy and are an excellent replacement for floats or other mechanical devives.

In certain cases, an ultrasonic level transmitter can be used to provide continuous measurement 4/20mA output signal, proportional to liquid level. This signal can be sent to either a digital display, PLC or other controller.

Industries: Oil & Gas, Power Generation, Wastewater, Chemical, Manufacturing, Paper, Petrochemical and Refining

Suggested Products

① LS7000

Point Level Switch for high or low level alarm detection

- Simple, reliable and low cost solution

- Solid state, no moving parts

- High level alarm - Prevent overfill or overflow conditions

- Low level alarm – Prevent run dry operations

- Secondary back up instrument – provides redundancy

② Ultrasonic

Continuous level measurement with ultrasonic in reservoirs with less than 30 psi.

- Provides accurate and reliable level measurement

- Easy setup and installation with single push button calibration

- Ignores peripheral obstructions

These are general product recommendations. For specific recommendations or help choosing the best instrument for your application, contact the factory directly or your local Babbitt representative.