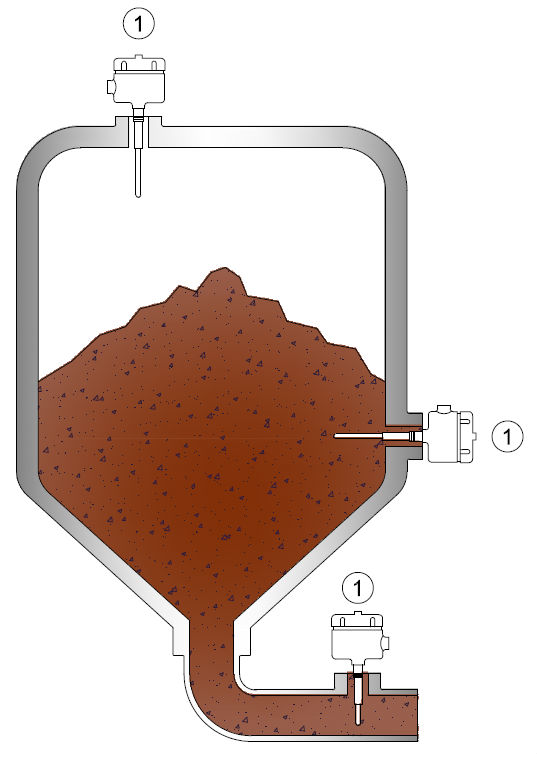

Point Level detection in powder and dry bulk solid storage tank, hopper, bin or silo.

Application

Storage tanks, silos and bins are commonly used throughout a variety of industries to store powders and dry bulk solid materials, including cement, flour, grains, lime, sand, plastic pellets and aggregates. Proper level monitoring of these materials not only prevents overfills, but also helps ensure materials never run out. Maintaining adequate levels of materials in these tanks is critical in achieving and maintaining operational efficiency.

Point Level Switches can be utilized for high or low level alarm as well as plugged pipe/chute detection. Optional cable style probes provide flexibility and are well suited for applications with large sized, heavy materials such as coal or aggregates.

Industries: Oil & Gas, Refining, Petrochemical, Wastewater, Cement, Power Generation, Food & Beverage, Aggregate, Paper and Recycling.

Suggested Products

① LS6000

Point Level Switch for high/low level alarm or plugged chute detection.

- Reliable and robust low cost solution

- Simple installation and calibration

- Ignores significant product build up

- No moving parts to get stuck, wear out or fall off

- Excellent replacement for rotating paddles or other mechanical devices

OR

① LS7000

Point Level Switch for high/low level alarm or plugged chute detection.

- Easy installation and calibration

- Adjustable time delay feature to avoid chatter

- Built-in test switch allows user to periodically test the circuit

- No moving parts to get stuck, wear out or fall off

- Ignores significant product build up

- Excellent replacement for rotating paddles or other mechanical devices

OR

① LS8000

Remote Mounted Point Level Switch for high/low level alarm or plugged chute detection.

- Avoid climbing tall tanks with remote mounted electronics

- Can be mounted up to one mile away

- Easy installation and calibration

- No moving parts to get stuck, wear out or fall off

- Ignores significant product build up

- Excellent replacement for rotating paddles or other mechanical devices

These are general product recommendations. For specific recommendations or help choosing the best instrument for your application, contact the factory directly or your local Babbitt representative.