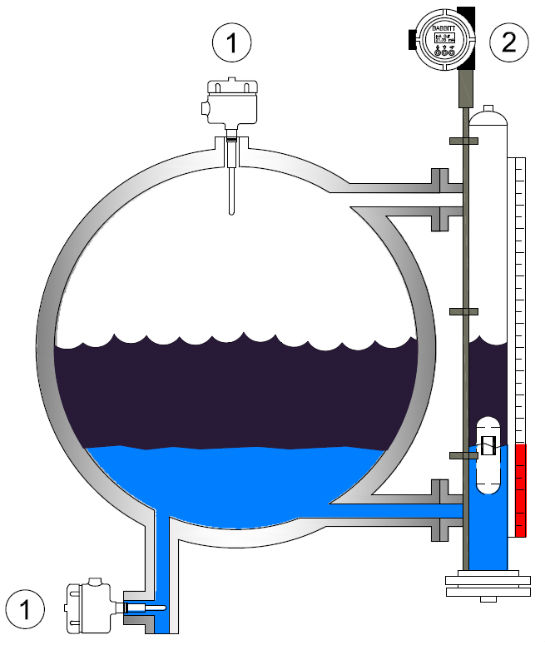

Point level detection and continuous level measurement in separators.

Application

One of the key operations in oil production is the separation of oil from water. Interface levels inside of separators must be continually monitored to protect against the inadvertent loss of oil during the separation process.

Point level switches can be utilized as high level alarms to prevent overfills as well as low level alarm detection to prevent oil from escaping through the drain pipe. These units can also be side mounted into a vessel or tank and used as interface level detection.

Magnetic Level Indicators provide visual level indication and can be coupled with side mounted transmitters for continuous level measurement. Adjustable MLS switches can be added for alarm set points – providing an all in one solution.

Industries: Oil & Gas, Food/Beverage, Petrochemical, Chemical and Refining.

Suggested Products

① LS7000

Point Level Switch for high and low level alarm detection.

- Simple, reliable, low cost alarm solution

- Solid state, no moving parts

- High level alarm - Prevent overfill or overflow conditions

- Low level alarm – Prevent oil from escaping

- Provides redundancy to other instruments

② Magnetic Level Indicator and transmitter

Visual and continuous measurement of level and/or interface.

- Safe, accurate and reliable level measurement

- Fluid never contacts the glass – no hazing - excellent replacement for sight glasses

- Easy to read visual scale can be seen from over 100’ away

- Optional continuous level transmitter and MLS Alarm switch provide all in one solution

- 2 float configuration can be used to measure both level and interface values

These are general product recommendations. For specific recommendations or help choosing the best instrument for your application, contact the factory directly or your local Babbitt representative.