The DP20T is a heavy duty, maintenance free low pressure transmitter designed for fabric filters, cyclones, powder processes and low pressure particulate laden pipes.

The unique flush/ported design enables configuration for either differential or static movement. The ability to transmit accurate measurements below 10 W.C., over a broad temperature range without clogging, makes the DP20T the ideal replacement for mechanical or helical devices.

Overview

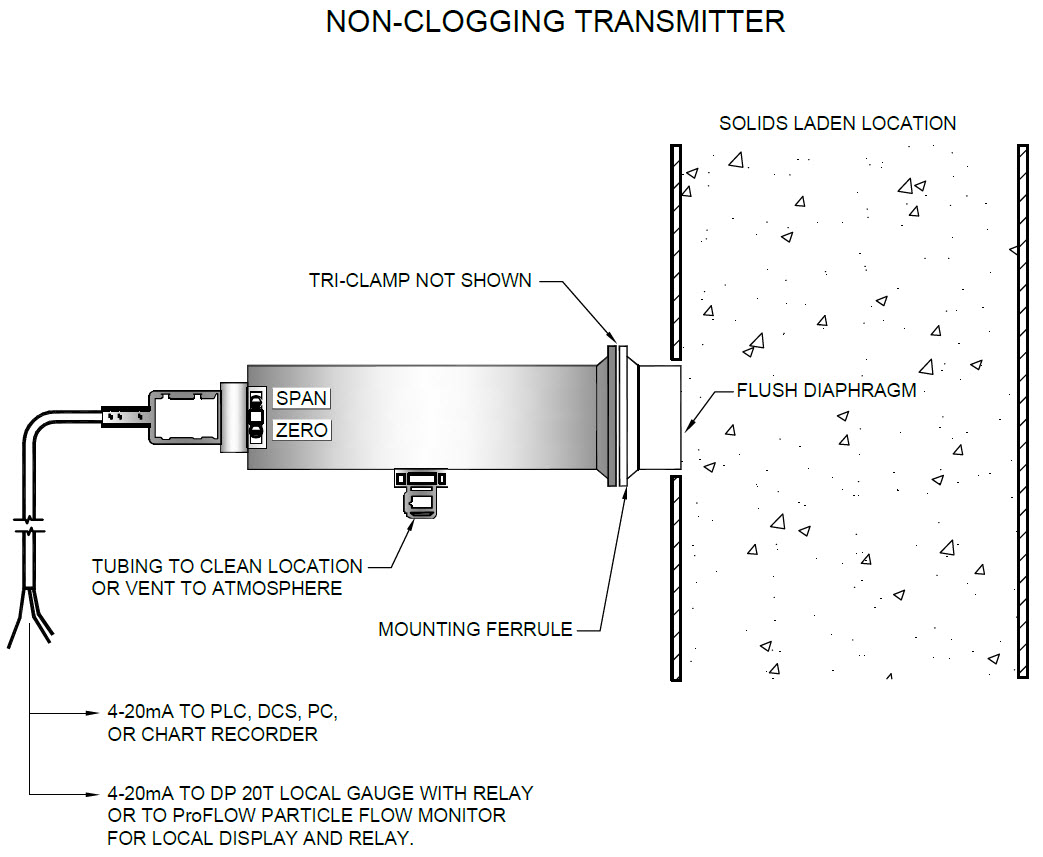

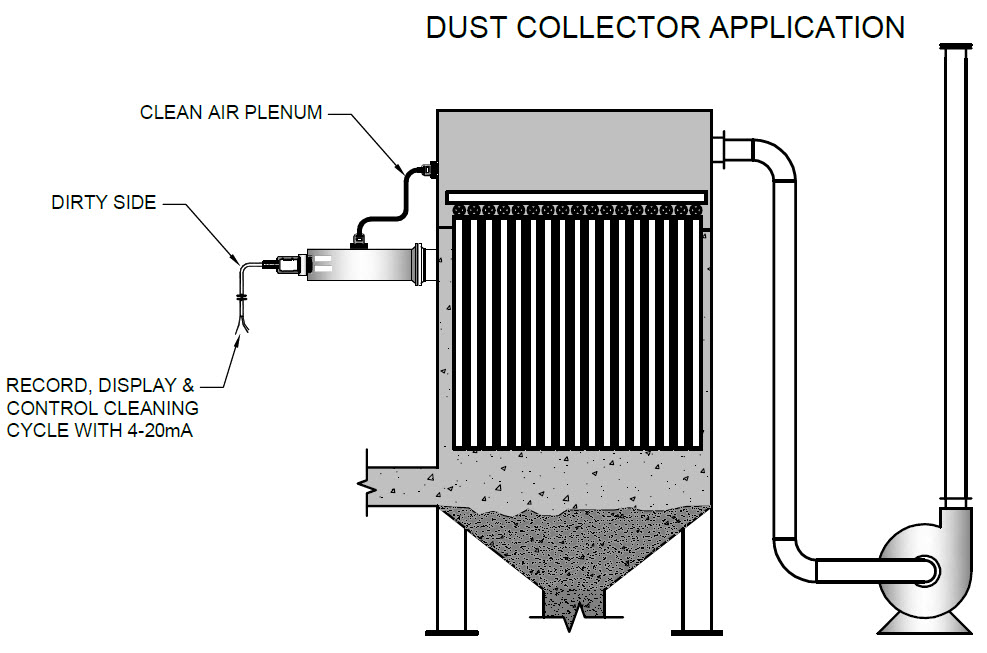

For differential measurements the flush diaphragm is mounted to the dirty or wet side of a process, such as the inlet of a dust collector, wet scrubber or mist eliminator. The port is used to route tubing to the cleaner side of the process such as the clean side of a dust collector or mist eliminator. For static measurement, such as in a powder conveying pipe, the port is simply vented to atmosphere.

Standard output is a 4-20mA signal for connection to a PLC, DCS, PC or chart recorder. For local display and relay control, a programmable panel mount LCD gauge is available (consult factory).

The DP 20T uses a state-of-the-art micro machined sensing element with temperature compensation packaged in a heavy duty stainless steel body. Changes in process pressure or vacuum applied to the diaphragm cause deflection in the sensing element. A precise, linear 4-20mA output signal proportional to the pressure or vacuum is produced by the circuitry.

DP20T Transmitter

Features

- Solid-state micro machined sensing element

- Temperature compensated, operate at temperatures up to 450F

- Accurate and repeatable 4-20mA output signal

- Heavy duty body prevents errors from mounting stress

Applications

- Ideal for Bag-houses, cartridge filters and cyclones

- Wet/Wet design for scrubbers and mist eliminators

- Static measurement for powder and solid flow pipes

- Intrinsically-safe version for hazardous locations

- 3A Sanitary rating for Food and Pharmaceutical industries

Benefits:

- Replace photomechanical/helical devices that clog

- Record differential pressure to meet EPA Regulations

- Ensure reliable pressure activated filter cleaning

- Integrate with Dust Emission monitors to optimize filter cake and maximize filtration efficiency

Specifications

Configuration and Ranges

- Configurations: Differential Wet/Wet Static Wet/Wet

- Ranges: 0 - 10 WC standard (other optional)

- Action: Positive at diaphragm

- Negative at diaphragm

- Bi- directional, optional Proof

- Pressure: 50 WC for 0-10 WC range (Higher consult factory)

Accuracy and Performance

- Total Error, Diaphragm at 200F: <1.5% FS

- Total Error, Diaphragm at 280F: <3.0% FS

- Based on zeroing at ambient. Zeroing at temperature reduces error.

- Response Time: 500 microseconds

- Resolution: Infinite

- Orientation Sensitivity: 0.03 psi/G

Electrical

- Supply Voltage: +13 to 32VDC

- Connection: 1/2 NPT exit with 5’

- cable Load Impedance: 950 ohm at 32VDC

- Output: 4-20mA

- Intrinsic safety: Consult factory

- Explosion-proof: Consult factory

Mechanical

- Diaphragm: Polished 316L SS, other optional Case

- Material: 304L SS, other optional

- Fill Material: NEOBEE M-20

- Housing: NEMA 4X equivalent

- Mount: Tri-clamp flange

- Port Connection: 7/16-20 UNF

- Weight: 16 oz.

Installation Kit

- Includes: Mounting ferrule

- Tri-clamp & gasket

- Differential port connectors

- 10’ Differential port tubing

*Specifications Subject To Change

Ordering

Information

For more information on ordering, please contact the factory.