Ultrasonic Level Transmitters provide reliable, cost-effective continuous level measurement of fluids in plastic or metal tanks, sumps, containers or other vessels that do not contain foam, vapors, fumes or gases. Integrated temperature compensation improves accuracy and the transducers, built-in self-cleaning operation reduces buildup or condensation. High-efficiency narrow beam technology helps eliminate unwanted echoes from standpipes, tank walls or other structures. Single push-button calibration and Gateway software make commissioning quick and easy.

Overview

Babbitt Ultrasonics Level Transmitters operate on the Time-of -Flight principle. The sensor generates a pulse that sends a sound wave from the transducer face down to the fluid level. The media reflects the signal and the transit time is converted into a 4/20mA output signal.

The proprietary circuitry uses smart signal processing to lock onto echoes farthest from the transducer face. This allows the unit to ignore peripheral obstructions when mounting close to vessel walls, piping or ladders. Sensors are designed to adapt to the internal tank conditions, automatically adjusting power and receiver sensitivity to any distance and reflecting surface. This technology ensures the same echo is maintained over the entire operating range, enhancing measurement accuracy. See video below for a short demonstration.

Sanitary Ultrasonic

The sanitary ultrasonic is the ideal solution for non-contact continuous level measurement insanitary/hygienic liquid-level applications. These units have a 316L stainless steel transducer face and are available in either 1 ½” or 2” tri-clamp mounting with a maximum range up to 30 feet. The sanitary stainless-steel ferrule allows for process temperatures up to 266°F while the HTP (high temperature and pressure) option can withstand clean-in-place (CIP) processes up to 266°F and 72 PSI for ½ hr. Available in 2-wire (HART) or 3-wire/4-wire (RS232/RS485) power Options.

High-Temperature Ultrasonic

The high-temperature ultrasonic is the ideal non-contact, continuous liquid-level measurement solution in applications with high-temperature processes. These units have a corrosion-resistant Teflon transducer and are rated up to 266°F (130°C). High-temperature ultrasonic level sensors provide self-cleaning, maintenance-free operation and plug-and-play installation with simple calibration. Available in 2-wire (HART) or 3-wire/4-wire (RS232/RS485) power options and ranges up to 60 feet.

Contact Us

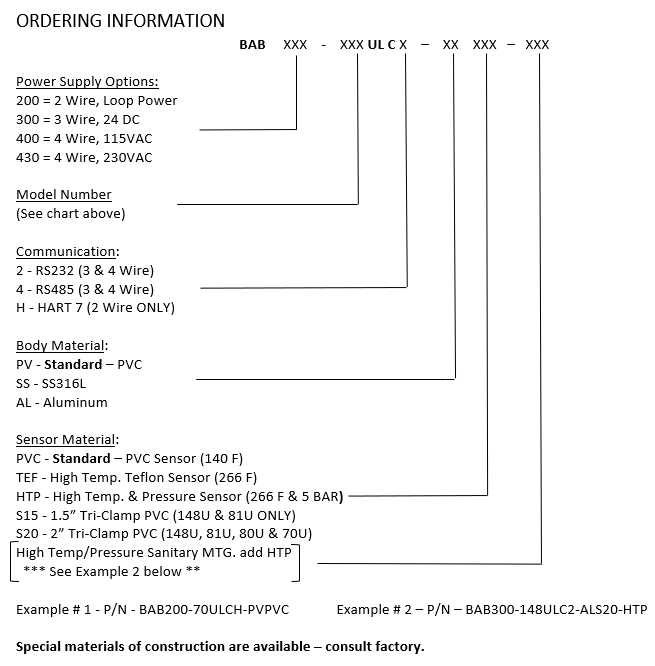

For ordering information, refer to ordering information below. Not sure what model is right for your application, fill out the data application PDF. Proper mounting and installation are critical to operation, refer to Owner’s Manual for instructions.

Features

- 4-20mA or 20-4mA output

- Offered in 9’ to 90’ measurement ranges

- Self-cleaning face eliminates condensation

- Smart signal processing ignores peripheral obstructions

- Built-in temperature compensation

- Corrosion resistant PVC transducer with IP68 enclosure

- Configuration via push button or Gateway software

- Non-volatile memory-batteries not required

Industries

- Water/Wastewater

- Food/Beverage

- Chemicals/Oils

- Viscous Fluids/Slurries

- Pharmaceutical

Applications

- Water without foam

- Liquids without methane, CO2 and H2S

- Water and solid mixtures

- Oil without H2S

- Inks and water based paint containers (low fume)

- Sanitary applications with CIP

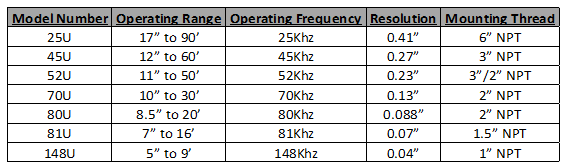

Specifications

Electrical

Power: 115VAC/60Hz, 230VAC/50Hz, 12-30VDC or 2 Wire Loop Power

Output: 4/20mA or 20/4mA, 6.1uA resolution 750 ohms, isolated w/ AC supply; non-isolated w/ DC supply

Fuse: 0.125A/250V type 2AG

Mechanical

Process Entry: Threaded per chart

Conduit Entry: ½”NPT – plastic conduit

Transducer: PVC Standard; Teflon Optional

Enclosure: PVC-94VO Standard; Aluminum and Stainless Steel Optional

Environmental

Temperature: Standard PVC (-40 F to 140 F); Optional High Temp with Teflon Transducer (-40 F to 266 F)

Pressure: Standard Models (15 PSI Max.); Optional HTP Sanitary or special High Pressure sensor (72 PSI)

Approvals: General Approvals CSA and FM; must have Aluminum enclosure

Operational

Dead Zone/Range: Depends on model, see chart

Accuracy: +/- 0.25% of span

Lost echo hold time: 30 seconds/output 22mA or 2mA – User programmable

Specifications subject to change without notice

Software Downloads

3 & 4 Wire Communication Software (rev 7.3) → Download Here

2 Wire HART 7 Communication Software (rev 2.9) → Download Here