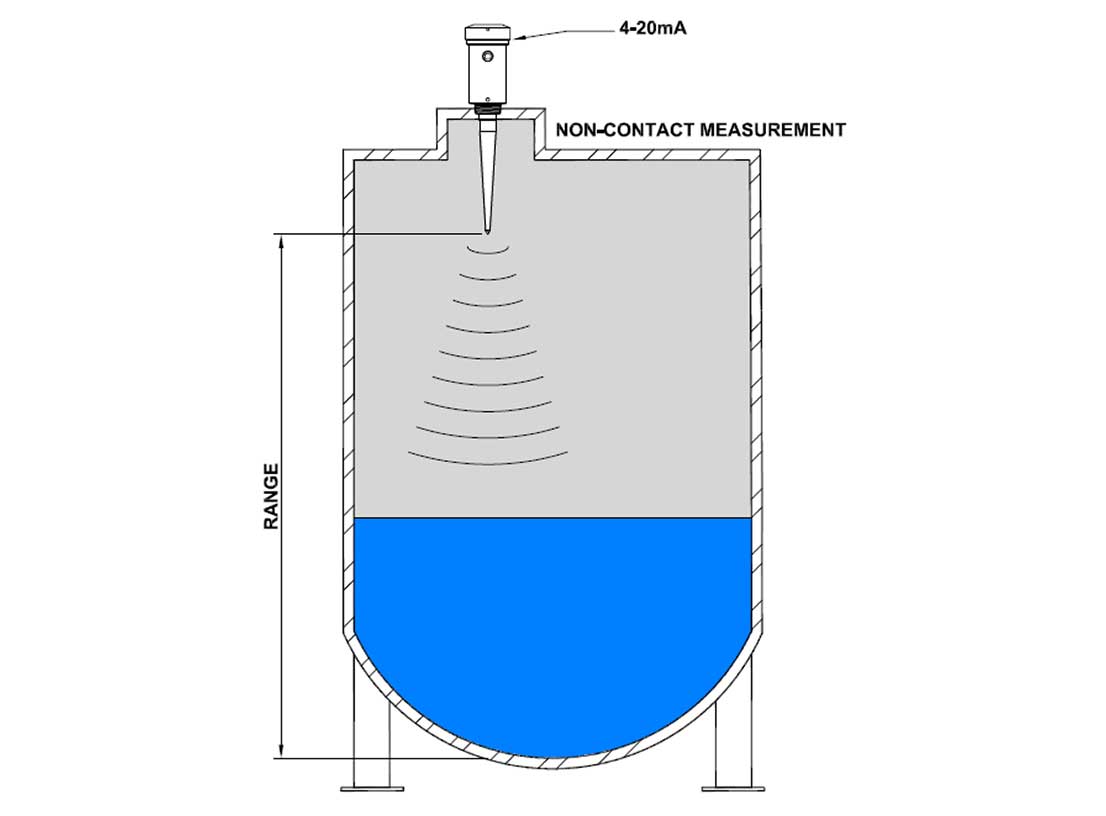

Radar Level Transmitters offer reliable non-contact, maintenance free continuous measurement of liquids inside metal tanks or vessels. Designed to operate in environments with more extreme process conditions, such as in a vacuum, high pressure, high temperature, foam, vapor or other gases that would normally interfere with ultrasonic type sensors. Perfect for use with corrosive liquids, thick fluids, slurries or other applications where direct contact with the media would not be desired. Low dielectric feature allows for operations in liquids with dielectric constants of 2 or greater. Broad range of models and options available to meet a wide variety of applications.

Overview

Babbitt Pulse Radar Level Transmitters operate on the Time-of-Flight principle. The microprocessor-controlled electronics transmit an electromagnetic pulse down to the fluid surface. The media reflects the signal and the time of flight is measured and converted into an output signal, which can then be sent to a display, PLC or other controller.

Proprietary software senses and analyzes the amplitude and shape of received echoes. This enables the units automatic gain control to track the process level as well as help eliminate echoes from unwanted obstructions. Low Dielectric Mode allows for use in liquids with dielectric constants of 2 or greater. Setup and commissioning are quick and easy. Calibration can be performed using the single push button or via the factory provided software. The Gateway software enables diagnostics, data logging and advanced calibration settings not accessible via the push button.

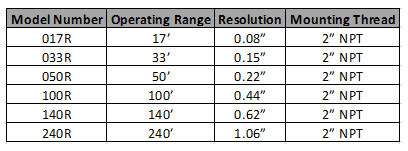

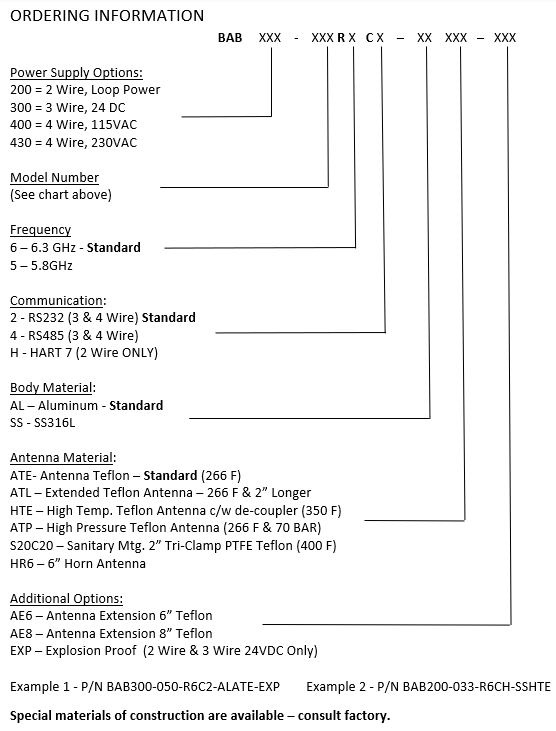

Babbitt offers a full range of Radar level measurement models to meet your applications needs. Various models, options and features include measuring ranges 17’ to 240’, high temperature, high pressure, sanitary connections as well as different power supply choices including 2 Wire Loop with HART communication. Optional Explosion Proof Approval for 24VDC and 2 Wire Loop Models. External relay controllers with programmable set points and alarms are available.

For ordering information, refer to ordering information below. Not sure what model is right for your application, fill out and submit the data application PDF. Proper mounting and installation are critical to operation, refer to Owner’s Manual for instructions.

Pulsed RADAR Level Transmitter

Features

- 4-20mA or 20-4mA output

- Unaffected by vapors or fumes

- Smart Sensor technology keeps beam narrow

- Simple configuration via push button or Gateway software

- Low Dielectric Mode for measurement of non-conductive liquids

- Non-volatile memory-batteries not required

- PLC compatible (Modbus RTU)

- Optional communication – RS232, RS485 or HART

Industries

- Water/Wastewater

- Food/Beverage

- Petrochemical/Chemical

- Oil and Gas

- Paint and Pigment

- Bulk Liquid Storage

- Marine

- Flammable/Corrosive Liquid Storage

Applications

- Liquids with foam, gases (CO2,methane) and other fumes

- Highly corrosive liquids such as acids and solvents

- High temperature applications up to 350F such as asphalt

- Slurries

- Acids, Caustics and Solvents

- Vacuum applications

- Diesel crude oil

- Sanitary applications

- Oil-water interface monitoring and detection

Specifications

Electrical

Power: 115VAC/60Hz, 230VAC/50Hz, 12-30VDC or 2 Wire Loop Power

Output: 4/20mA or 20/4mA, 6.1uA resolution 750 ohms, isolated on AC supply

Fuse: 0.125A/250V type 2AG

Mechanical

Process Entry: 2” NPT

Conduit Entry: ½”NPT

Antenna: Teflon

Enclosure: (Standard) Aluminum; (Optional) Stainless Steel

Ingress Protection: NEMA 6 (IP68)

Environmental

Temperature:

-40 F to 140 F (Electronics)

-40 F to 250 F (Teflon Ant.)

-40 F to 350 F (Teflon Ant. And Teflon De-Coupler)

Pressure: (Standard) 75 PSI Max. (Optional) 1000 PSI – 70 bar – without de-coupler

Approvals: (Standard) FM (USA) FM3810 (2005) ANSI/NEMA 250 (1991)

FM (CAN.) CSA C22.2 No. 1010.1 (2004) CSA C22.2 No. 94 (2011)

(Optional) Explosion Proof FM & CSA for Can. & US Explosion Proof

Class I, Div.1, Groups B, C, D: Dust-Ignition Proof Enclosure for

Class II/III Div. 1, Groups E, F, G

FCC Part 15 – Low communication Device

Operational

Range: 17 to 240 feet -Depends on model

Accuracy: +/- 0.25% of maximum target range in air

Frequency: 6.3 GHz (other frequencies available upon request)

Transmitter Power: 50uW average

Lost echo hold time: 30 seconds/output 22mA

Specifications subject to change without notice

Software Downloads

3 & 4 Wire Communication Software (rev 7.2) → Download Here

2 Wire HART 7 Communication Software (rev 2.8)→ Download Here